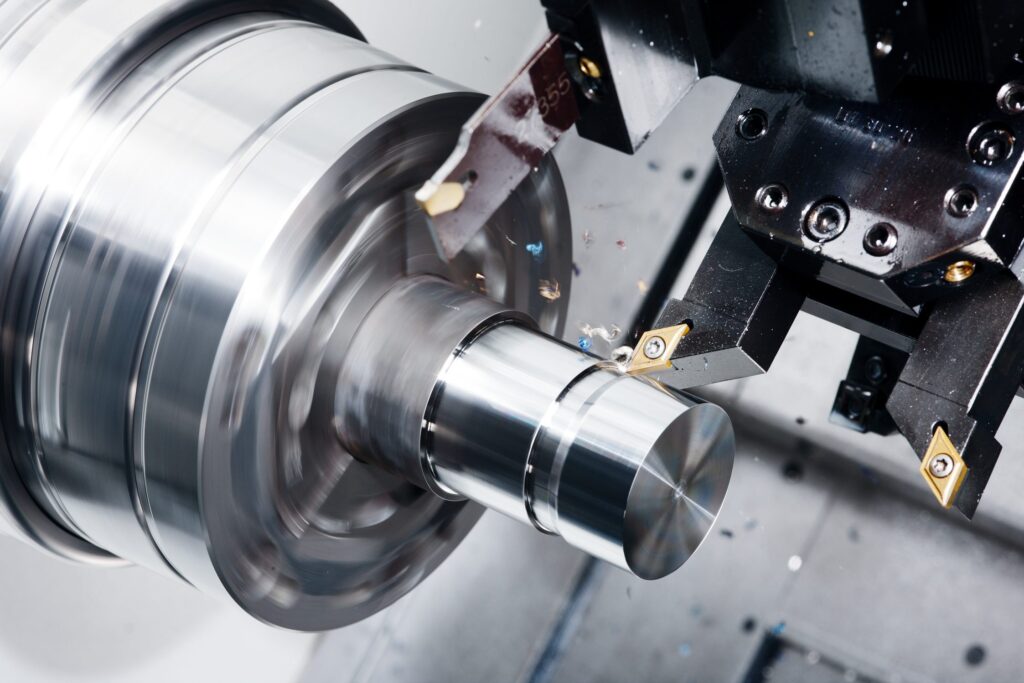

The process in which machines parts by “turning” a rod material is CNC turning. The material is shaped into a finished product and the rod is fed by using a cutting tool. The cutter is usually fed by a rotating workpiece which typically uses diverse tool shapes as well as a variety of different angles. The parts that are symmetrical near their axis (like a Chess pawn would be a part that is symmetrical near its axis) are created in this CNC Turning process. However, the shapes created by these products can vary greatly through. Moreover, the possibilities are endless in other machining processes. While most people create turned parts that only utilize a single axis by using CNC Turning. However, for more flexibility, they can also use ones that have more than one axis.

However, cnc turned parts suppliers can be your best partners if you are looking for pre-eminent quality and cost-effective CNC turned parts. There are many manufacturers available in the market who offer good quality CNC turned parts at affordable prices all around the world. So you can easily place your order according to your need. However, these skilled professionals can also benefit your business from their experienced advice.

Some of the most versatile material range is briefly discussed in the below paragraph. Keep reading and you will be able to choose the most advantageous one for your business:

Cooper CNC Turned parts

However, cooper is very famous due to its hardness, extraordinary strength, and electrical and thermal conductivity. Moreover, cooper is easy to mold in different shapes and designs because of its flexible nature. Their corrosion resistance is making them a better choice for many electronic and industrial appliances.

Stainless Steel CNC

Stainless steel is a widely common material in CNC turning projects due to its dynamic tensile strength, high performance at variable temperatures, efficient corrosion, and wear-resistant properties. However, to ensure high-performance outcomes, stainless steel provides increased tolerance and high accuracy. Moreover, it is a time-saving and wallet-friendly material.

Brass CNC

These are the best materials in CNC turning projects. It produces less co-efficient friction, fast-speed operations, tight seals, corrosion-resisting capabilities, and smooth finishes. However, to achieve high-precision parts with stability and flexibility with brass components and high machinability. Moreover, they are low-cost end products and time-saving as they are capable of producing parts quickly.

Aluminum CNC

Aluminum CNC turned parts are the best option if you are looking for cost-effective and high-quality products for your business. Moreover, they have flexible machining properties and are soft, lightweight, and resistant to cruel chemicals.

Titanium CNC

By using titanium, you will get many benefits rather to other materials. However, some of the major and useful advantages of titanium are: they possess abrasion resistance and high strength properties against salt and water.

Alloy Steel CNC

These are the type of materials in which steel alloy with other metals, creates a robust and impactful substance. Some of the characteristics of Alloy Steel are:

- Anti-corrosion Ability

- High Hardness Tolerance

- Wear Resistance

- Strength

- Recyclable

Read More https://yijinsolution.com/

More Stories

What 2025’s Credit Limits Mean — And How to Access Cash Fast

Integrating Information Usage Fees in Mobile Wallets for Seamless Transactions: A Comprehensive Guide

Complete Guide to Selling Digital Products Using MicroCommerce