Ever since technology and manufacturing have gotten in sync in all. Possible ways, the wire EDM machine process has certainly become the hero behind it all.

It is mainly used in precisely intricating machine parts and. Certain materials which cannot be processed by the conventional. Approach or methods.

With the potential and benefits of this process. It has been expanded to almost all manufacturing industries and is still empowering people worldwide. The key reason behind the wire EDM machining process’ popularity is the cost-effective approach and efficiency it provides to the process.

This process is mainly used for the conductive parts. This machining process provides the liberty to the manufacturer to create any type of shapes and patterns from the materials that are from the hard category like stainless steel, titanium, and other types of alloys that are hard. You should also be aware of the fact that three types of EDMs are available in the market. Let’s try to learn a little more about the topic with the help of this article.

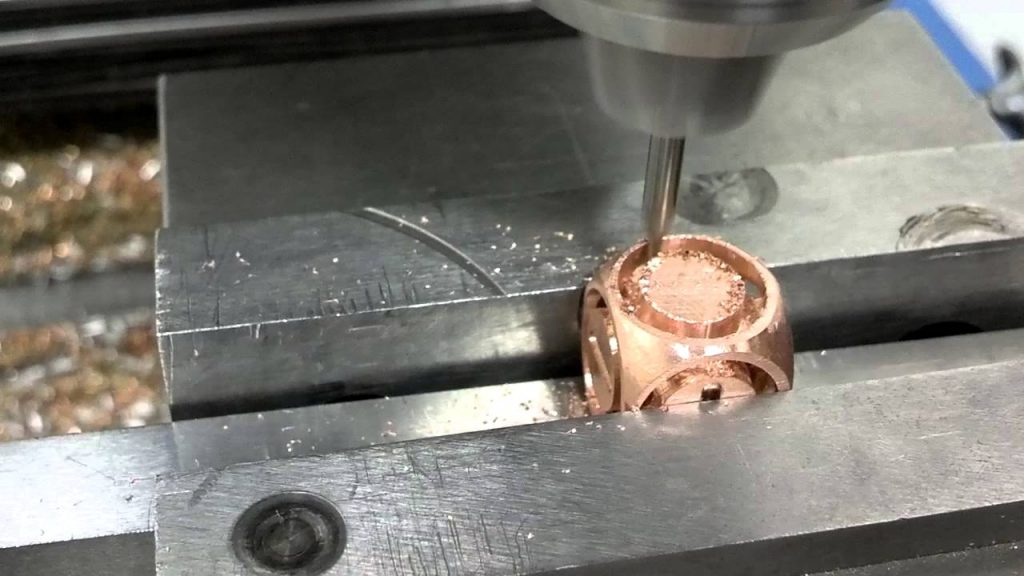

Wire EDM Machining

In this process, an electrically charged. Wire is constantly used against a dielectric fluid.

This resulting discharge that was produced is then presented to the CNC with a grounded material in its vicinity and is used to carve the conductive material according to the desired design.

Wire wire EDM machine makes an electrical release between the workpiece and the wire/terminal.

Then, at that point, an electric flow is gone through them to make the flashes. The flashes are dependable to assist with framing the picked state of the part.

At whatever point the distance among the cathodes gets limited, the power of the electric field increments, and hence, the dielectric liquid becomes more grounded. Because of the present circumstance, the current passes effectively between the two terminals and the part gets isolated from the metal sheet with each flash delivered

Benefits of using Wire EDM machining

As the process of Wire EDM machine has been the core behind all the processes associated with the manufacturing process, there are certain separate advantages to it as well.

Let’s discuss some of them right here:

Complex parts can be produced easily

Probably the most important use of the EDM machining process is for carving and creating complex pattern and shapes with the help of electric charges.

Well, you might be thinking that shapes can be easily created with the help of some other process, what is new in this one?

Well, the key reason behind using this is that it can alter the shape of the hardest materials available in the market. The process of wire wire EDM machine is generally used to penetrate hard and fragile materials.

A cost-effective approach

Using this process for the processing of hard materials completely rules out the energy that is needed to cut the rigid materials.

And since this process is so precise and accurate, it completely reduces any kind of material wastage in the process. Another advantage of using the Wire wire EDM machine process is that it doesn’t demand any post-operation touch-ups. The final product doesn’t need any processing because the whole process delivers precise and top-notch quality results.

High tolerance

The Wire EDM machining process is popular because. It can used on the most complex and rigid materials as well.

Applications of wire EDM machining

If you’re thinking that the wire EDM process is just limited to creating only delicate items, then you should have a look over the applications given below:

- It is widely used in blanking punches and. Some of the most common extrusion dies.

- The automobile and aerospace industry also gets the benefits of this machining technique.

- Some life-changing implantable medical devices are possible just because of this one-of-a-kind machining technique.

- Hole drilling processes on soft and hard materials

- Helps in making prototypes

Pros of using wire EDM machining

- The EDM machining process is an example of the self-threading process. It means that if the wire breaks while cutting a certain material, it doesn’t affect the pace of the whole process. The operation can continue without any delays.

- This fabrication method provides us with the best quality parts as compared to the parts produced with the help of some other techniques.

Cons of using wire EDM machining

- Like we’re already aware of the precise product that these machines deliver, the spare parts and consumable items associated with these machines can be expensive. And the expert worker who’s responsible for handling the machine with precision is not available everywhere.

- The wire process is only limited to conductive materials.

Conclusion

There are a lot of benefits of incorporating wire EDM machining into your manufacturing process. So, what do you have to lose? We can also assist you if you’re seeking a dependable machining partner.

IQ Manufacturing is a well-known brand in the manufacturing business for offering high-quality wire EDM machining solutions at a low cost. So, what are you waiting for? To learn more,

More Stories

What 2025’s Credit Limits Mean — And How to Access Cash Fast

Integrating Information Usage Fees in Mobile Wallets for Seamless Transactions: A Comprehensive Guide

Complete Guide to Selling Digital Products Using MicroCommerce